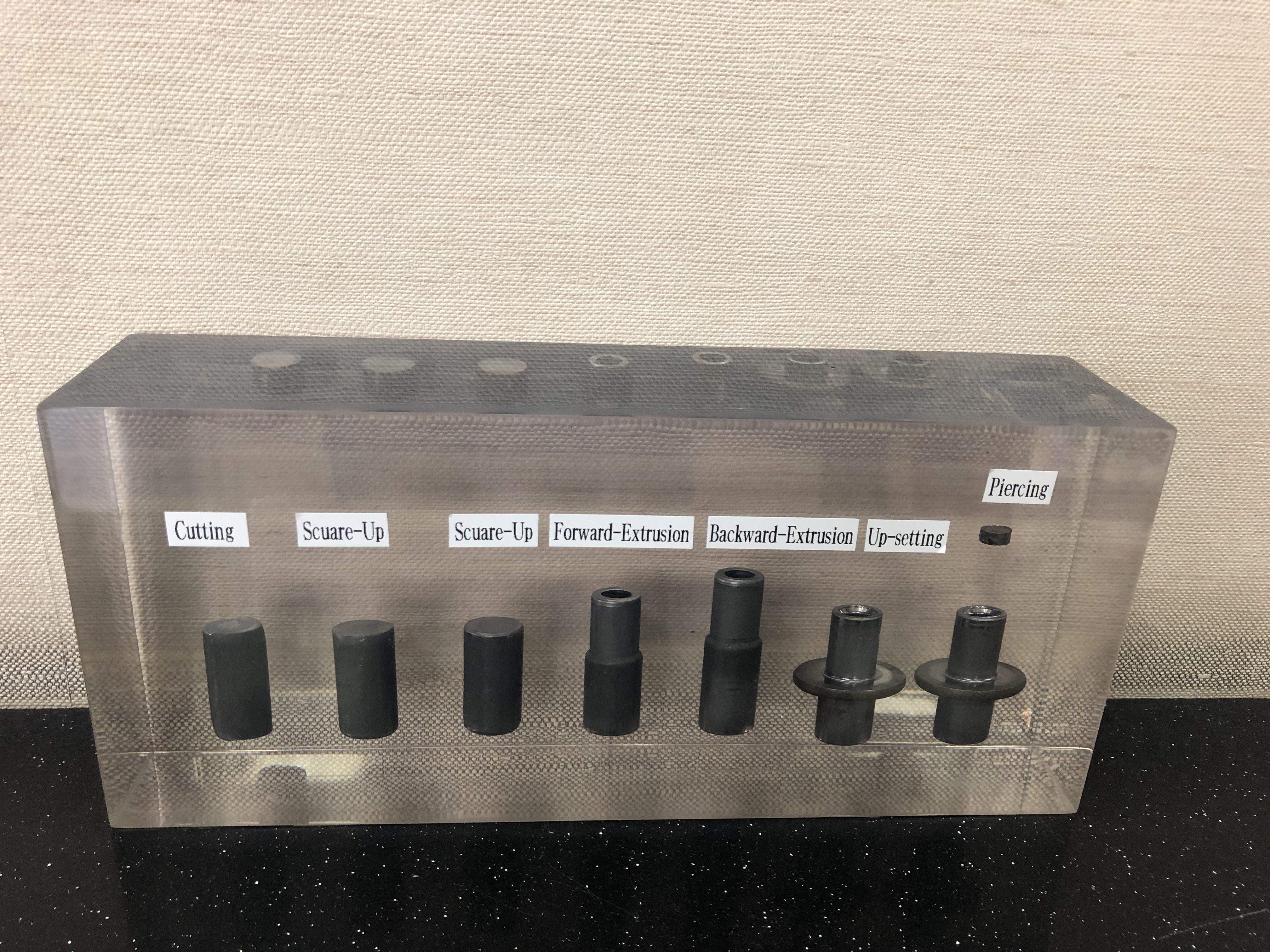

Process sample

Equipment introduction (corresponding size, material, etc.)

Cold heading is a type of technology which is based on the application of pressure to metal in order to shape it in a room temperature environment.

The material used is coil material. Not only iron but also non-ferrous metals such as stainless steel, aluminum and copper can be processed, although there are certain restrictions.

We can handle anything up to φ7.5-φ23 diameter in material, secondary processing, two former machines, tap machines, and even rolling machines.

NP160

| Number of steps | 2x3 3 punches, 2 dice |

|---|---|

| Forging wire diameter | Φ7.5~φ16 |

| Neck length | 135 |

| Cutting length | 16~170 |

| Forged head diameter | 35 |

| Features | Basic perforated products are not allowed. Good at complex shapes with short-sized products |

(May differences depending on the above mentioned machine specification dimensions, as well as the material and shape during the time of manufacture.)

Achievements in Indonesia

・Reclining hinge

・Seat-related BOLT

※ In Japan, we have a track record of manufacturing hinge-type PINs for sliding doors.

HBP623

| Number of steps | 6 steps |

|---|---|

| Pressure wire diameter | Φ9.5~Φ23 |

| Neck length | 140 |

| Cutting length | 10~160 |

| Forged head diameter | 32 |

| Features | Efficient at manufacturing hollow products, through-hole products, drawn products, etc |

(May differ depending on the above mentioned machine specification dimensions, as well as the material and shape during the time of manufacture.)

Achievements in Indonesia:

・COLLAR system

・PISTON system

・PIPE system

Indonesian product results introduction

An Introduction to the secondary processing machine

Rolling

Tap

Frequently Asked Questions

-

Q.01

What is cold heading?

-

Cold heading (also known as cold forming) is the process of molding metal through pressure at room temperature through the use of tools such as hammers and dies, without heating the material.

Compared to hot heading, there is less heat-based distortion, and is a technique that is characterized by a high processing accuracy.

-

Q.02

What are header and former machines?

-

The header refers to the process of "hitting the head". Generally, headers have up to 2 molding processes, and formers have 3 or more molding processes.

-

Q.03

What are the benefits of cold heading?

-

There is almost no material loss involved in the process.

When mass-produced, it can be manufactured at a lower cost, by comparison to cutting (the mold fee is required on a separate basis).

Because it is casted within the mold, products with stable dimensions can thus be mass-produced.

So as to perform the plastic manufacturing process within the mold, the fiber flow (fibrous structure) is left uncut, and is therefore stronger than the cut product.

-

Q.04

What is the minimum number of lots?

-

Although it depends on the material and the unit weight of the specific product, 10,000 units are generally desired for an estimation in regards to the cost of the header processing.

-

Q.05

What is the wire diameter of the material?

-

Φ7.5-Φ23 are the measurements used within the current Indonesian facility.

-

Q.06

What is the maximum product size?

-

Please feel free to contact us regarding this issue, as it depends on the specifications of the equipment.

-

Q.07

Is it possible to perform secondary processing (thread cutting, tapping, drilling, cutting, etc.) and surface treatment (plating / heat treatment) in addition to cold heading?

-

Yes, we can provide support in that regard. However, we do not accept requests for secondary processing only.

-

Q.08

What if I don't have a drawing and am in possession of only a sample?

-

We will make a drawing based on the item. If you are unsure of the specifics of the material, we will propose it after having a consultation.

PT. FUJI SEIMITSU INDONESIA

PT. FUJI SEIMITSU INDONESIA